The CH-100 Tamper Evident Band Applicator

-

+ Stepper motor driven

-

+ Butterfly mandrel

-

+ Pneumatic cutting blade

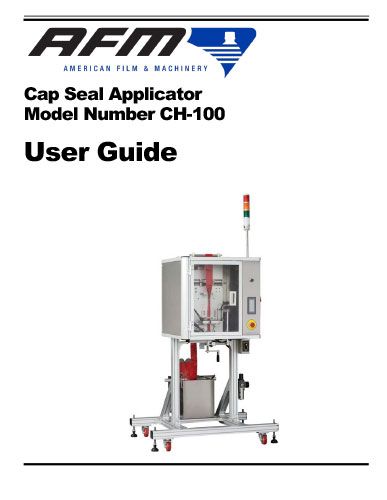

The CH -100 Tamper Evident Band applicator from American Film & Machinery is an economy-level shrink band applicator designed to apply tamper-evident bands on a variety of containers. The CH-100 is designed for low to moderate production rates and is a perfect solution for industries including food and beverage, pharmaceutical, nutraceutical, health and beauty, consumer goods, chemical, and other manufactured goods.

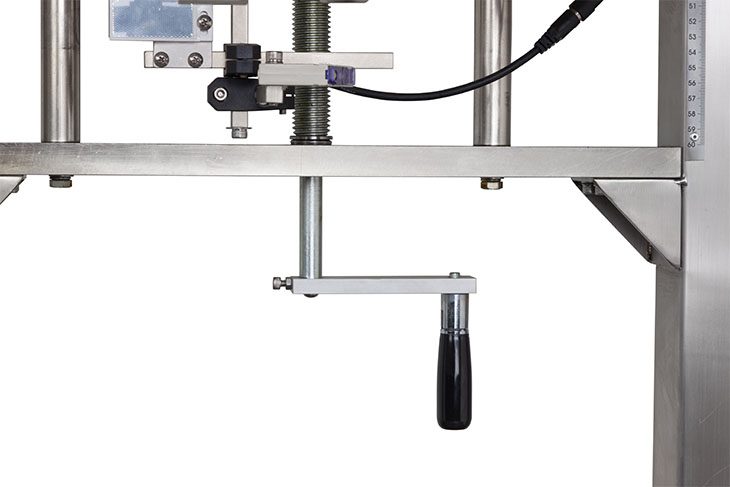

Industrial Design

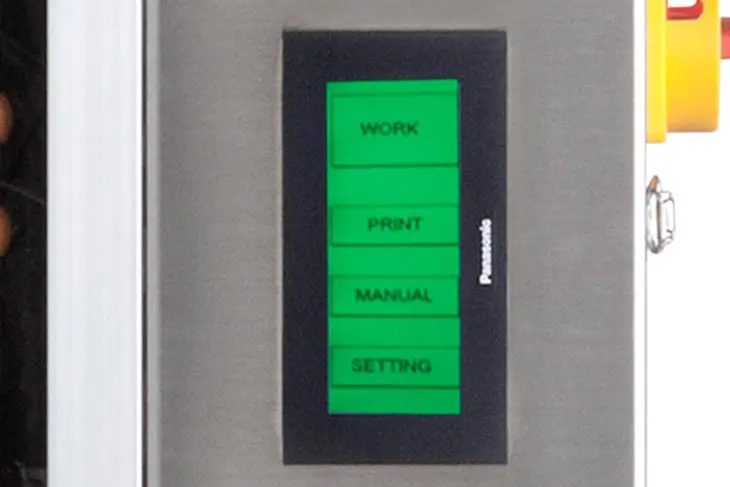

The CH-100 is a fast and efficient butterfly mandrel-style tamper band applicator engineered to meet the demand of your workflow. Designed for 24-hour operation, CH-100’s simple and low-maintenance design allows for quick film change and maximum uptime. CH-100’s compact housing is constructed from 304-grade stainless steel and anodized aluminum to provide strength and reduce vibration while offering quiet operation. Product runs are programmed with a user-friendly touch-screen control interface, making setup and operation fast and easy.

Around The Clock Operation

CH-100 Tamper Band Applicators are designed with stepper motor driven, single film unwind with tension control, cutter assembly, and pneumatic cylinder to provide accurate and consistent tamper band application. CH-100 has been engineered to handle round bottles made of plastic, glass, or metal at speeds up to 120CPM. The single-blade guillotine cutting mechanism provides extremely smooth, even cutting of PVC/PETG film 50 to 70 microns in thickness.

STANDARD COMPONENTS OF THE CH-100

- Stepper motor driven

- Butterfly mandrel

- Pneumatic cutting blade

- Photo-eye for registered cutting

- Single unwind system and tension control

TECHNICAL SPECIFICATIONS OF THE CH-100

- Power: 1 Phase 220V

- Film Thickness:05mm – 0.07mm

- Film Lay Flat: 40mm – 150mm

- Cut Length: 20mm – 50mm

- Machine Dimensions: 1000mm (W) x 1130mm (L) x 1620-2000mm (H) 39.4” (W) x 44.5” (L) x 63.8” – 78.7.6” (H)

- Speed: 20 – 120CPM; timing screw required for speeds 75 – 120 CPM

OPTIONAL FEATURES & COMPONENTS FOR THE CH-100

- Label tamp-down device

- Timing screw or wheel