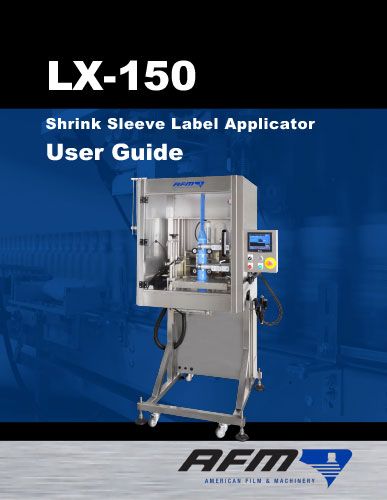

The LX-150 Shrink Sleeve Label and Tamper Evident Band Applicator

+ Round cylindrical mandrel

+ Round Cutter

+ Single round 400 mm timing screw

The LX-150 Shrink Sleeve Label and Tamper Evident Band applicator from American Film & Machinery is a mid-range labeling machine designed for middle, full body, and full body and cap applications. The LX-150 is designed for low to moderate production rates and is a perfect solution for industries including food and beverage, pharmaceutical, nutraceutical, health and beauty, consumer goods, chemical, and other manufactured goods. Due to the versatility of the system, the LX-150 is also ideal for the changing needs of contract packagers.

Increase Your Workflow

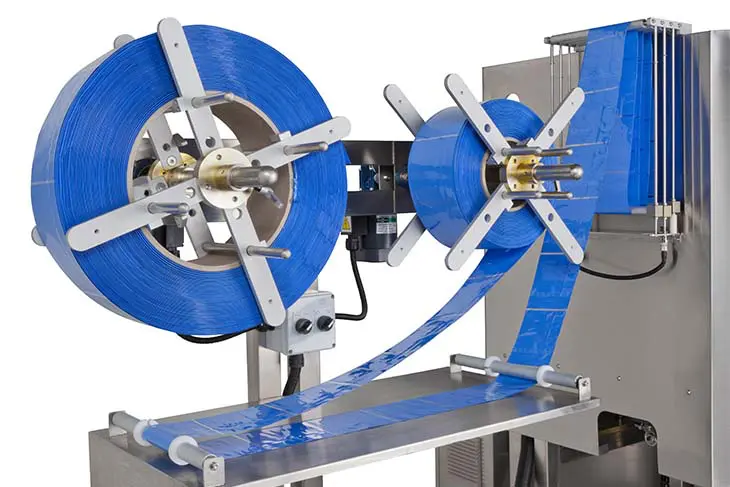

LX-150 is an in-line single-head mandrel-style labeling system engineered to meet the demand of your workflow. The LX-150 can be rolled up to any conveyor to provide accurate shrink sleeve placement of up to 300 products per minute. The machine’s sturdy Good Manufacturing Practices (GMP) design and construction provide for 24-hour operation, while its standard dual unwind system allows continued operation with only a brief splicing stop. Product runs are programmed with the user-friendly touch-screen control panel HMI, featuring standard and custom menus that can be password protected for an added layer of security.

Guaranteed Precision. Quick Changeover.

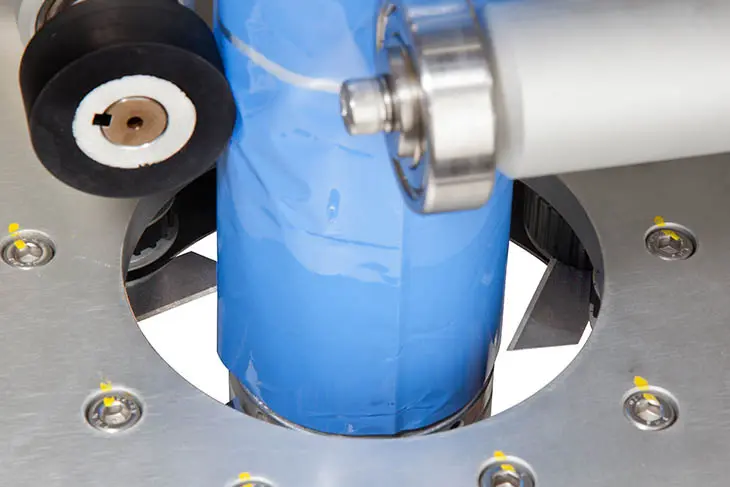

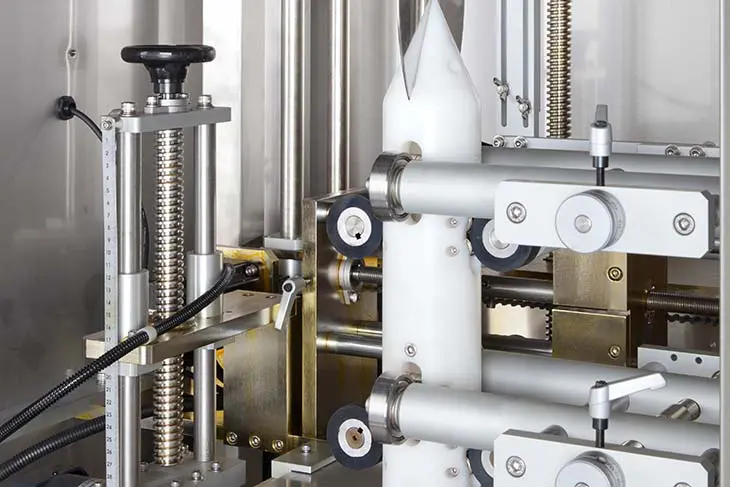

Size changeovers are simple and quick. The cut length can be changed electronically by utilizing the control panels’ touchscreen interface. For different product diameters, a new timing screw and bullet (mandrel) can be installed in minutes, while different product heights are accommodated by raising or lowering the machine with a turn-screw mechanism. The LX-150 comes with our quick change system for switching mandrels with a turn of a knob. Along with the mandrel, the cutter assembly has only two levers to turn, keeping your downtime to a minimum.

- Round cylindrical mandrel

- Round Cutter

- Single round 400 mm timing screw

- Photo eye for registered cutting

- Label brush down device

- Dual roll unwind system and tension control

- Power: 220V/3ph/20A or 480V/3ph/10A; 50/60 Hz

- Film Thickness:035mm – 0.07mm

- Film Lay Flat: 40mm – 240mm

- Cut Length: 40mm – 200mm, or modification to 70mm – 250mm

- Machine Dimensions: 853mm (W) x 1090mm (L) x 1850-2150mm (H) 33.6” (W) x 42.9” (L) x 72.8” – 84.6” (H)

- Speed: 50 – 300CPM

- Irregular mandrel, timing screw, and cutter for non-cylindrical containers

- Dual belt drive system for stopping label for mid-body label applications

- Vertical and T-Perforation units

- Label tamp-down device

- Dual 400mm and 800mm timing screw assemblies for irregular containers